Resin Art epoxy

R405,00 – R1725,00Price range: R405,00 through R1725,00

- Perfect for Resin art applications

- High viscosity

- Fine processing with pigments

- Transparent casting with domed gloss (doming)

Use Personal Protective Equipment when working with epoxy resin.

The Resin Art Epoxy is the epoxy for your artwork!

Mixing ratio by weight: 100 Parts A : 60 Parts B.

Advantages:

- Crystal clear epoxy, UV stabilized for long-lasting clarity guarantee.

- Glossy and scratch-resistant surface.

- Good adhesion to substrate.

- Water-resistant after curing.

- Can be used outdoors due to its UV resistance after curing.

- Self-degassing and self-leveling.

Disadvantages:

- Cannot be poured thick due to high viscosity (up to 3 MM).

- Not recommended to cast transparent layers more than 3 MM thick.

Resin Art Epoxy:

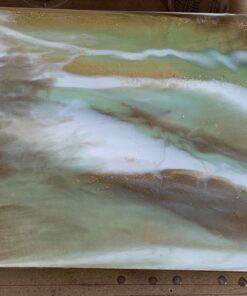

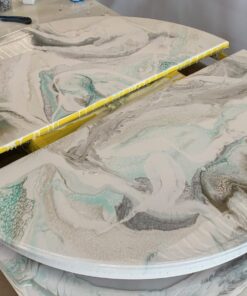

This casting resin is intended for creating your own artworks by combining it with epoxy pigments. The epoxy resin has a high viscosity, which means it’s thicker. This thickness ensures that pigments stay well suspended in the resin, making colors stand out even more. Use it also as a transparent protective layer for other artworks. This resin has a beautiful dome gloss that gives your artwork a 3D effect. Let your creativity run wild.

Check out our Instagram for inspiration. Be amazed by all the possibilities with Resin Art and check out the tutorials to see what you can create.

Combine the Resin Art Epoxy Casting Resin with our Metallic and Transparent Pigments!

With these pigments in combination with this epoxy casting resin, you are assured of a unique result. Pigments stay in place better due to the thickness of the epoxy resin, thereby

How to use Resin Art Epoxy :

TIP: First, make sure that the object you want to cast is leveled.

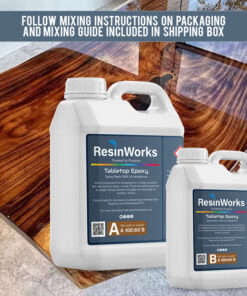

Our epoxy casting resin is easy to use. The product is supplied in 2 parts. So 1 part A-component Epoxy and 1 part B-component hardener. These parts must be mixed together before casting your project.

The mixing ratio by weight of this product is 100 parts A : 60 parts B.

It is recommended to mix the products in mixing cups.

Using mixing spatulas instead of an electric mixer is recommended. This ensures that the product remains air-free, resulting in fewer air bubbles in the epoxy casting resin. During the casting, you will experience air bubbles rising to the surface. These are easily solved with a gas torch or the bubble pop spray. By spraying one dose of the bubble pop spray over the surface, you will see the bubbles disappear.

You can also choose to carefully go over the object with the torch. The epoxy should not be heated too much as this causes uneven curing. This can result in a poor outcome.

Product properties:

- The working time of the product is 45 minutes at 20 degrees.

- Minimum processing temperature is 15 degrees.

- The maximum layer thickness is set at a maximum of 0.3 centimeters or 3mm.

- Dust dry after 12 hours. Can be recoated after 18 hours.

- To cast a surface of 1 m2 with 1mm, you need 1 kg.

- After complete curing, the surface has a hardness of 85 on the Shore-D Scale.

- Due to this high hardness, the surface has a scratch-resistant finish. (High degree of scratch resistance)

TIP: First use the casting resin to seal your object so that you don’t see your epoxy disappearing into the tabletop during casting.

Applications:

- Casting a kitchen countertop in color.

- Casting a side table.

- Creating beautiful artworks.

- Making epoxy jewelry.

- Create organites.

- Creating coasters

What do you get?

With an order of the resin art epoxy Casting Resin, you receive:

- A-Component Epoxy

- B-Component Hardener

- Mixing guide

| Weight | N/A |

|---|---|

| Dimensions | N/A |

Be the first to review “Resin Art epoxy” Cancel reply

Related products

All items

All items

All items

All items

Reviews

There are no reviews yet.